Terminal Blocks and Multi-Connector Systems

The terminal bocks and multi-connector systems by PTR are divided into two groups: a) screw terminal blocks, and b) spring terminal blocks. Three connection types are available for the screw terminal blocks: the wire guard, the lift, and the excenter type.

Normally, screw terminal blocks are manufactured either as modular constructions, as two-pole and three-pole terminals, and can be flexibly connected to each other to make larger terminals by means of the so-called dovetail connection. Individual series are also available in blocks. Screw terminal blocks using the different connection designs are available with spacing from 2.54 mm to 15.24 mm, metric or inch, and in various colours.

A multi-connector system consists of a pin stripe which is fastened onto the PCB and the relevant terminal block (also known as a socket terminal strip or connector). Three connection types are available for the screw terminal blocks – the wire guard, the lift, and the excenter type. Normally, screw terminal blocks for multi-connector systems are manufactured as a block design and are available using the different connection types with spacing from 3.5 mm to 15.24 mm, metric or inches, and in various colours

PTR wants our customers to keep in touch with the latest developments, and the fields of use for PTR terminal blocks and multi-connector systems are suitably diverse. They are used from automation technology, safety technology and telecommunications, to building automation. And because quality isn‘t something which can be left to chance, all PTR terminal blocks and multi-connector systems are VDE and UL approved or currently undergoing the approval process.

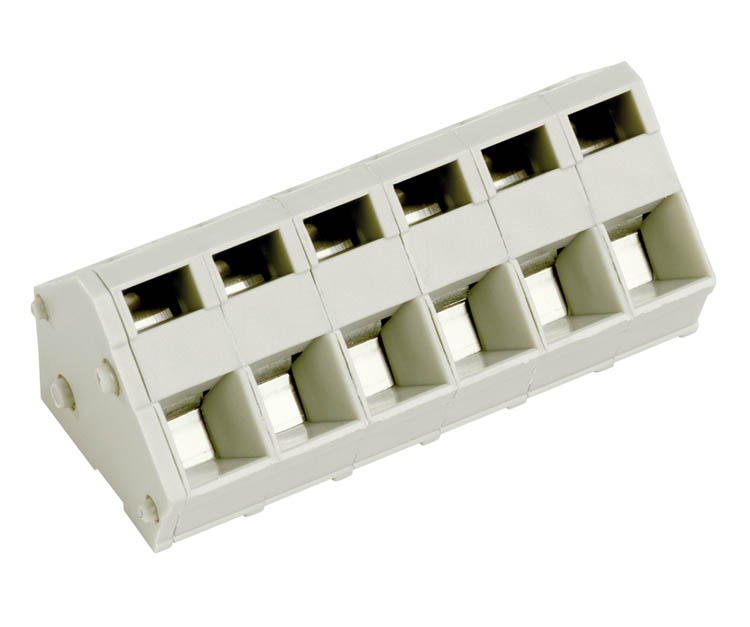

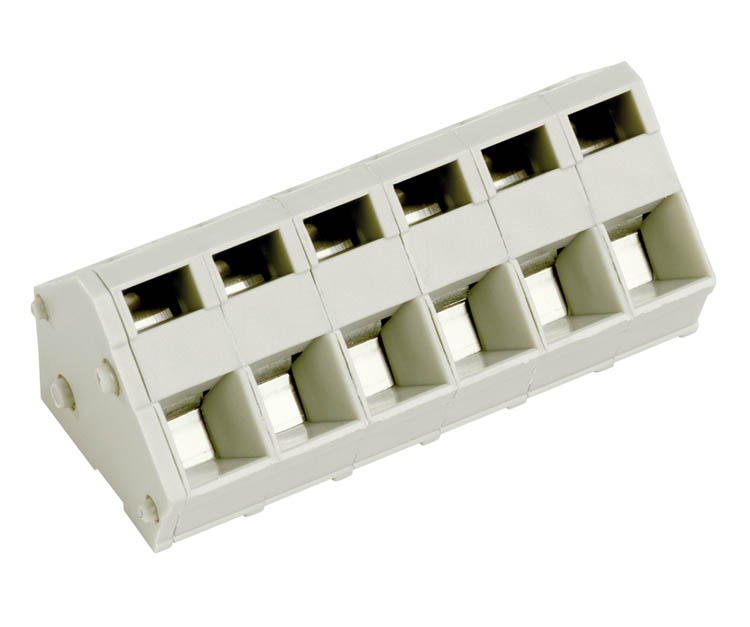

Screw Terminal Blocks - Wire Guard by PTR

In this design, PTR screw terminal blocks make use of stainless steel wire protection which protects the connected wire. The solder pin and clamp body form a single unit, and this guarantees low transition resistance and minimal voltage loss. This configuration allows for (a) a versatile and low-cost solution for terminal blocks whose terminal clamps are rarely removed; and (b) the use of both solid and stranded conductors with and without ferrules. Applications include building automation, safety technology, and telecommunication.

Screw Terminal Blocks – Lift by PTR

The most popular and proven technology for connections which must often be removed consists of terminal

blocks with a lift design which allows the clamp to move parallel to the solder tag during the screwing process. This ensures that it is

easy to detachand restore the electrical contact. It also ensures secure fastening in the clamping area of solid or stranded conductors with a wide range of wire sizes. The wire is clamped between the clamp and the solder tag, so even the smallest wires fit tightly in the connection area. The lateral grooves in the connection area provide excellent tear strength and ensure penetration of the wire’s oxidation layer when the screw is tightened. This creates a secure, gas-tight electrical connection. This connection mechanism is used for industrial applications when it is necessary to connect and disconnect conductors frequently, but at the same time to ensure a reliable electrical contact.

Spring Terminal Blocks - Push-In by PTR

The push-in design by PTR offers the fastest connection method. It is ideal for use with solid and stranded wires with ferrules, and allows the user to make connections by direct insertion of the wire without using a tool or pressing a lever. A screwdriver or operating lever is necessary only to open the spring during the insertion or removal of stranded wires. The simple structure of terminal blocks creates a compact design. The data and telecommunication industries often use this time-saving connection technology.

Terminal Blocks, Spring Terminal Blocks - Tension Spring by PTR

The tension spring design allows the user to connect and disconnect wires by opening the spring with a screwdriver or operating ever – there is no time-consuming rotation of a screw or need for a special tool. The tension spring type is very useful in difficult operating conditions, for example where there is a risk of vibration, impact, shock or extreme temperature fluctuations. The spring compensates for the stress-dependent and thermal compression/ flow performance of the wires, and this ensures a gas-tight and maintenance-free electrical connection. This dynamic clamp connection system creates a reliable contact, protects the connection against vibration, and is becoming more and more popular in industrial and traffic technology applications.

Akkus und Batterien

Akkus und Batterien

Aktive Bauelemente

Aktive Bauelemente

Automatisierungstechnik

Automatisierungstechnik

Chemische Hilfsmittel

Chemische Hilfsmittel

Elektromobilität

Elektromobilität

Elektronische Kühlung

Elektronische Kühlung

Gehäuse

Gehäuse

Kabel und Adapter

Kabel und Adapter

Löttechnik

Löttechnik

Mechanische Bauelemente

Mechanische Bauelemente

Messtechnik

Messtechnik

Montagezubehör

Montagezubehör

Netzwerk und Computer

Netzwerk und Computer

Optoelektronik

Optoelektronik

Passive Bauelemente

Passive Bauelemente

Protective Cases

Protective Cases

Rohkabel

Rohkabel

Sensorik

Sensorik

Sicherungen

Sicherungen

Steckverbinder

Steckverbinder

Stromversorgung

Stromversorgung

Werkzeuge

Werkzeuge